|

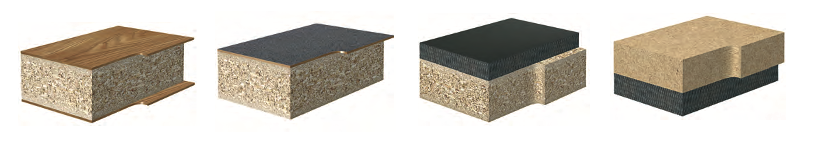

Trimming cuttersThese are used to trim one surface back to match another, e.g. when facing boards with laminate or veneer. It is much easier to cut the laminate oversize and then trim it back flush to the workpiece after it has been stuck down. The router will leave a square or shaped edge depending on the cutter you use. Although there are some trimmers that require the use of the side-fence, most are self guided with bearings. When the bearing is the same diameter as the cutter it is called a flush trimmer and is available in various configurations that allow you to trim either one or two faces at once. They are particularly useful for template work. Pierce and trim cutters are used to form internal cutouts for sinks, hobs and other inset fittings. For this purpose, the opening is first cut in the worktop core prior to the application of the face laminate or veneer. The laminate area within the opening is then pierced through with the drill point of the cutter, allowing the pin guide to be run around the internal edge of the opening, trimming the laminate back perfectly. Before using bearing guided trimming cutters, make sure that the adhesive used to apply the laminate or veneer is thoroughly dry. If not, it is likely to clog the bearing and prevent it from turning. Also, remove any glue deposits from the edge of the base material and the overhanging edge of the laminate, as this will cause the bearing or side-fence to be lifted away, leaving an uneven edge to the finished work.   |

|

|

Cookson Hardware, Stockport, Greater Manchester UK Online Architectural Ironmongers Thursday 24th April 2025 |